The Objectives of Inventory Management: Techniques, Challanges and Process in Detail!

Inventory management is an essential process of tracking the stock of products. It helps companies to be more profitable since its basic principle is to hold costs. In this article, you will learn about the objectives of inventory management in depth.

Have you ever thought about the products a workplace has, and how they manage them? So, imagine you are about to enter a bakery and buy a muffin. From the ingredients that are used for making the muffin to the muffin itself; each item that played role in the process is an inventory and needs to be managed properly. The same applies to corporate businesses as well as local shops.

What Are The Objectives of The Inventory Management System?

Inventory management objectives are expected to be operational and financial. Operationally, stocked goods should be available in sufficient amounts and financially, working capital should be minimized as possible. Here are some main objectives of inventory management.

Fulfilling the orders

Firstly, you can’t meet a received order if you don’t exactly know how many of those products you have in hand. To fulfill the orders, you must have the right products available in times of need. Otherwise, orders might put you in chaos.

To clarify, assume that you are selling toys; you received an order of 100 boxes but when you check out, there are in fact only 50 boxes available in the warehouse. The sales representative takes the order of toys without knowing the situation in the warehouse and here comes the mess.

Then, to not experience this, the objectives of the inventory management system should be used and team members should be knowing the inventory situation.

Having sufficient supply with Objectives of Inventory Management

Secondly, from raw materials to the finished product, inventories should be readily stocked in advance. You should supply the required material in enough quantity so that products do not suffer at the time of a customer need.

Tracking supply is a way to make sure that stocks are ready to meet the customer’s needs. It also gives the opportunity to shape the demand based on the existing supply. You can set certain goals directed to customer demand only if you have enough supply to meet such demand.

Controlling stocks

Thirdly, you need a systematic record of inventory to run things more smoothly. Having this system makes you control your stocks and prevents you from various confusion such as duplication in orders or keeping the inventories in the wrong amount. Overstock or understock situations should always be considered.

We already know that understocking might cause scarcity and also ruins the ordering process, but overstocked products are no less risky than that.

Suppose that you are working with spoilable materials and you overstock them. Maybe you intend to keep those inventories as a backup in case of greater demand than usual.

However, storing way too much of them may cause you more trouble than when you can’t meet the demand. They spoil before they get used and it eventually ends up with cost and extra effort.

Minimizing costs

The main point of inventory management is actually minimizing costs. You should be minimizing the unnecessary capital to be financially alright. Money is a crucial constraint after all. You should keep your investment at a minimum level and also keep the material cost under control to reduce the production cost.

When the items do not sell, your assets might suddenly become liabilities. Thus, one of the aims of inventory management is to ensure that you don’t lose any money by having the inventory. Items should be used while they have their original value.

Minimize your working capital as possible, since it is also necessary for other activities like operations and sales. When you effectively manage your inventory, you avert from such expenses as purchase costs, carrying costs, or storage costs.

Avoiding waste or losses

Inventory management is highly effective when it comes to dealing with losses. An item being wasted or lost is quite natural when there is not a proper tracking system.

Besides, theft is always a risk worth considering no matter what type of work you do.

Moreover, keeping a record of the items minimizes the odds of loss even if not eliminated. Having a record in hand prevents any possible waste and also keeps your company away from theft. Especially where there are massive amounts of products to be handled, such risks are even greater.

So, an inventory management system is a life-saver tracking everything and avoiding possible losses.

Enhancing overall production

Managing your inventory improves production at so many levels. When there is something you prefer to change in production, having the inventory system makes you do it faster.

Furthermore, if you want to scale or shrink your production, the first thing to do is look at your tracking system and decide how to lead the production.

Besides, in terms of ensuring an effective supply, inventory systems already help production run steadily. If you keep your records and hold enough supply, production doesn’t have to be restructured again.

Optimizing product sales

Additionally, another thing that you can use inventory management for is analyzing product sales patterns. Sales is a critical and important phase of the whole process. It helps to understand the current situation and make future assumptions based on the analysis. You can detect slow-moving goods for instance, and eliminate them.

Imagine you are selling cosmetic goods. Some of your products are not doing a great job in the market. Sales are not as predicted and all of them are waiting on the shelves. Keeping those goods that don’t sell anymore doesn’t seem like a good idea.

In that case, you can down the prices aiming to dispose of them, or even find another way to do it.

Inventory Management Techniques

Economic Order Quantity:

This is a formula being used for calculating the ideal order quantity and it aims to reduce overall costs. The purpose is to reduce inventory so EOQ stands for the lowest amount of inventory you need to order to meet the demand with minimum cost.

Pros

- Reduces holding and ordering costs

- Minimizes storage

Cons

- Requires continuous monitoring

- Requires detailed data for calculation

- Limited by assumptions

You can use Someka’s Order Planning Excel Template and Supply Planning Excel Template to manage your order and supply quantities.

Minimum Order Quantity:

It indicates the lowest amount set by the supplier for retailers to purchase. If you want to buy a particular product, you need to be able to purchase the MOQ.

Pros

- Gives the best possible price per unit available

- Allows suppliers to increase their profits

- Maintain a healthy cash flow

Cons

- Upfront costs might be intimidating

ABC Analysis:

It is a technique that categorizes inventory into three, based on their value in terms of sales. Category A represents the most valuable products, B is the mid-valued items and C is the least valuable ones.

Pros

- Provides accurate inventory

- Helps to forecast the demand

Cons

- Conflicts with other inventory systems

- Requires more resources than others

Just In Time inventory management:

It purposes to reduce inventory costs. Instead of ordering too much of a product, it allows companies to receive the needed amount of inventory.

Pros

- Lowers inventory costs

- Eliminates the risk of dead stock

- Improves cash flow

Cons

- Risk of stock out

- Might be complex to implement

Safety Stock Inventory:

It is an extra amount of inventory being kept in case of unexpected demand. It is important to determine the safety stock value in the right way.

Pros

- Protection for rapid changes

- Prevents stockouts

- Provides preparation for uncertain forecasts

Cons

- Safety stock is expensive

FIFO and LIFO of Objectives of Inventory Management:

FIFO means “first in, first out” and says that the first items in the inventory should be sold first. According to LIFO on the other hand, which stands for “last in, first out”, the last items in inventory should be sold.

Pros for FIFO

- Keeps inventory fresh

- Good for maximum capacity and high profits

Cons for FIFO

- May not show costs accurately when material prices rapidly increase

- Not advantageous when it comes to taxes

Pros for LIFO

- Has a tax advantage

- Helps prevent inventory from going bad

Cons for LIFO

- Requires complex recordkeeping

- Can be difficult to maintain

Reorder Point Formula:

It tells the lowest amount of inventory one reached, and when they should order more stock. It is calculated by multiplying “Average Daily Unit Sales” and “Average Lead Time in Day” and by adding “Safety Stock”.

Pros

- Helps to order the right amount of stock

- Protects from market spikes and slumps

Cons

- Overloading might occur when many items reached the level

- There is no set sequence since the items come up randomly

Batch Tracking:

It is also known as “lot tracking”, which is a process-tracing good along the distribution chain by using batch numbers. It allows us to see the whole journey of goods; where they came from, where they went, how much was shipped, and when they expire.

Pros

- Easy and fast recall

- Minimizes accounting errors

- Better relationships with suppliers

Cons

- It requires extra attention

Consignment Inventory:

This is a win-win agreement between wholesalers and retailers. A wholesaler gives their goods to a retailer, or consignee, without receiving the payment until when the retailer actually sells the goods.

Pros for wholesaler

- Lower carrying costs

- Chance to test new markets and products

- Direct marketing to the retailer

Pros for retailer

- Lower risk and increased cash flow

- Chance to return unsold goods without cost

- Having a wide product range without tying up capital

Cons for wholesaler

- Shipping costs into a large amount of new inventory

- Possible loss in case the products don’t sell

Cons for retailer

- Many inventory systems do not handle consignment inventory well

- Difficulty to manage the constant movement of the consigned stock on a spreadsheet

Perpetual Inventory Management:

This one is the most basic inventory management technique and all it needs to do is count inventory as soon as it arrives.

Pros

- Managing multiple locations easily

- Easy access to the system

- Provides up-to-date inventory information

Cons

- Setup costs could be intimidating

- Might require additional training for employees to use the system

Dropshipping:

This is a method in which your products are held by a third party and shipped directly to the customer. So, you receive an order; then forward your order to the supplier and the supplier handles the order for you.

Pros

- Low barrier to entry

- Minimizes inventory and order costs

- Increased cash flow

- Chance to test new products with less risk

Cons

- Lack of control

- High competition

- Disjointed orders

Lean Manufacturing:

This is an approach aiming to improve efficiency and maximize product value by eliminating waste and any non-value-adding activities.

Pros

- Less raw materials and finished products stocked

- Reduced lead times to finished products

Cons

- Requires the involvement of all employees in the methodology

- Requires a companywide overhaul of production systems

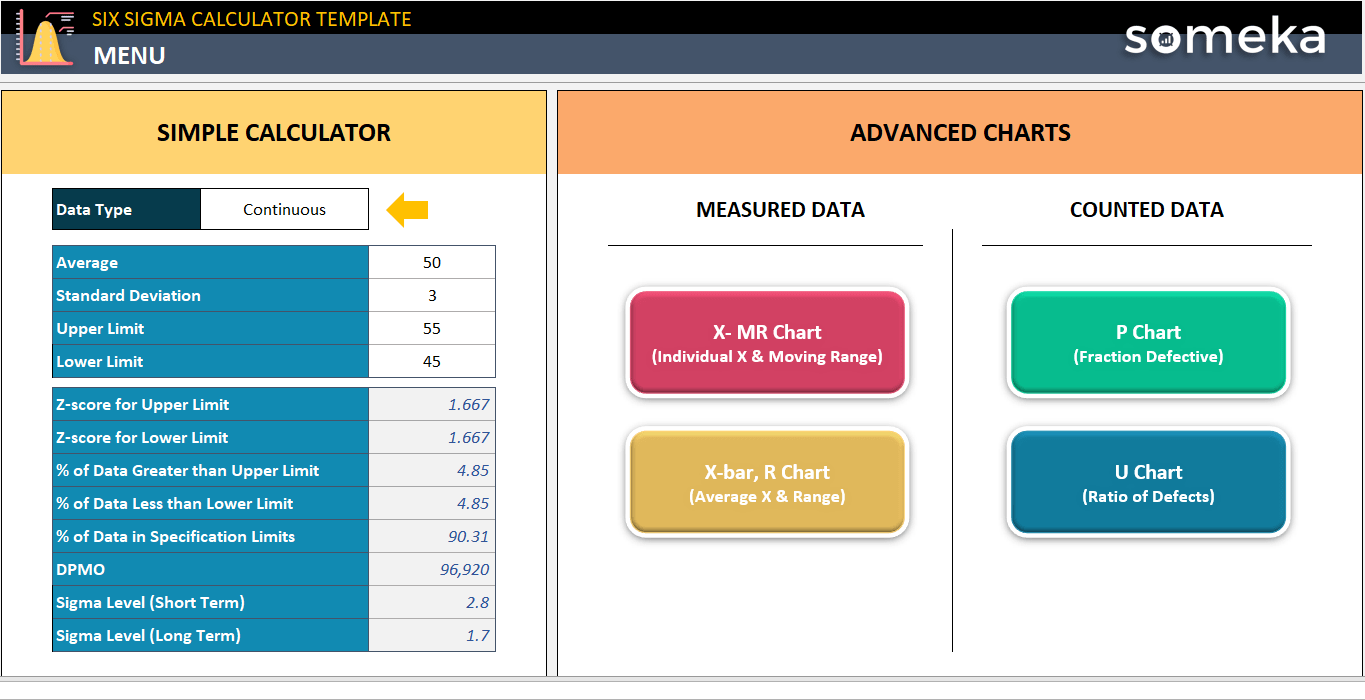

Six Sigma and Lean Six Sigma:

Six Sigma aims to improve the performance of businesses by increasing profits and decreasing the growth of excess inventory; Lean Six Sigma, on the other hand, easily enhances the tools of Six Sigma by systematically removing waste and reducing variation.

Pros

- Avoids wastage

- Increases value and quality

Cons

- Increased overhead and operational costs

- Difficult implementation

– Someka has a special template for Six Sigma Calculation –

Demand Forecasting:

It is basically predicting what, when, and how much customers buy products. It can be practiced based on evaluating past sales.

Pros

- Provides valuable insight

- Gives a starting point

- Increases overall profitability

Cons

- Not every situation can be predicted

- Might be time-consuming

Bulk Shipments:

This a cost-efficient technique that is used for palletizing inventory to ship more at once. This method can be applied to goods with high customer demand.

Pros

- Lower shipping costs

- Highest profitability potential

- Suitable for predictable demand and long shelf lives

Cons

- Increased storage holding costs

- The highest potential for capital risk

The Process of Inventory Management

1) Forecast the demand

Forecasting what will there be ahead waiting for you might be a good starting point to make proper inventory management. If you have the data, you can look at your past sales and make a prediction for possible future sales and accordingly arrange your inventory. If you are a new business and do not have such data, you can focus on market research and try to reach the optimal amount of inventory that will prevent you from stockouts and carrying costs.

2) Review your budget

Your forecasting data might be ready for starting your inventory management process, but you need to make sure that all expenses are within your budget. Reviewing your budget means determining how much you are able to cover with your order and also reviewing any price changes.

3) Plan your warehouse

After the budget, you need to plan your warehouse. Controlling the place where all the inventory lies is an important step in this process. You must take care of the storage conditions as different types of materials need different types of storage. Managing your warehouse also allows you to categorize your inventory; items would be placed based on the frequency of their sales so you would be able to optimize your warehouse space.

4) Make a preliminary order list

It is better to make a preliminary list of everything you need to order. That list should be created considering the previous amount of demand for your products. After making your list you should check your current and surplus stock, then update the list for the final order. You can use a form to prepare your list more clearly.

5) Choose a method

To clarify, you need to evaluate all the inventory management techniques and decide which one is the best for you. So, the point is to choose the very method that would cost you less and meet your needs. You can consider the pros and cons of each technique and make an optimal decision toward your process.

6) Find the right tool to implement the method with the Objectives of Inventory Management

Once you chose your method, you must have the right tool to implement it into your process. It might be difficult to choose between the wide range of tools in the market. To make it easier, consider some factors and reach the right tool for your needs.

- Select a price range and narrow your options down.

- Identify your needs and thereby know which tool would be better for you.

- Determine how you will track your inventory.

- Decide on the necessary integrations for your process.

There are certain options in the market when it comes to inventory management tools. You can try using software or you can use an Excel sheet and make your inventory process with a ready-to-use template.

Why Inventory Management is Important?

In today’s world, as systems get improved; inventory management comes with its complexities. Business volume is way more massive than ever before. The more we produce, the more we sell, and then comes the requirements. Inventory management makes you evaluate your business on a regular basis. There are many efforts behind controlling the inventory, but it surely prevents the company from various possible troubles such as stockouts or short supply. It partakes in a solution to today’s challenges.

Objectives of Inventory Management for Today’s Challenges

Challenge 1: Increased inventory turns

Requirement: Having the information as thorough as possible

Solution: An inventory management solution that keeps inventory data comprehensive and in detail.

Challenge 2: Increased stock-keeping units (SKUs)

Requirement: Being able to handle a growing amount of inventory, customers, and vendors

Solution: An inventory management solution that stores an unlimited number of products.

Challenge 3: Increased sales of e-Commerce and omnichannel

Requirement: Managing sales effectively from multiple channels

Solution: An inventory management solution that keeps track of sales whatever the channel is.

Using Excel for Inventory Management

Above all, inventory management exists because of the need of handling inventories, which means a workload that has to do in a systematic way. Tracking all the stocks of various products would have been a nightmare if they were being done manually. Luckily today, inventory management systems took the place of pen and paper. Certainly, now there are software and templates that make you save time and effort so that you can manage all your stocks with some clicks easily.

Excel, just like it helps their users to manage many operations in their business, provides a practical platform for those who want to make proper inventory management. Besides, Excel is affordable and easily reachable, and it is also user-friendly.

So, ease of use would be a priority assuming you are not likely to want to deal with complexities since the inventory process is already full of detailed data. Excel is always ready to use and doesn’t require installation.

There are many ready-to-use Excel templates for inventory management. All you need to do is download it and start using it. Let’s look at a Stock & Inventory Tracker Excel template and what type of features it offers.

Stock & Inventory Tracker Excel Template of Objectives of Inventory Management:

Basically, this “Stock In and Out Template” is constructed in 5 parts: the dashboard, the item list, the received products, sales, and settings. You basically input your data into the template and arrange them among the sections, then review your overall inventory report after all the purchases and sales. Someka has also a Google Sheet version of this template. Check Stock and Inventory Tracker Google Sheets Template for an online tool with access from all devices and a simultaneous work option.

– This is the Dashboard section of Someka’s Stock & Inventory Template –

Objectives of Inventory Management Settings:

It is the custom settings part in which you can set the product descriptions, categories, and unit types. Once you filled the columns in settings, you can go to the item list and input the product information for each row. You write their code, category, or even initial quantity, alert level, and remarks.

Subsequently, the initial quantity is how many of those products you have at that moment, while the alert level is the minimum quantity level that you agree to have. Then, when the final stocks get below the alert level, they will be shown on the dashboard in red. The remarks column, on the other hand, is where you can write your notes.

Received Products:

Most importantly, you can input the purchase dates, codes, received quantities, and purchase price. Just use the drop-down menu in the code column which is quite practical, and see how categories, products, and units will be updated automatically.

Sales:

To clarify, here you can input the date, codes, quantity, and price for sales this time. Category, products, and unit types columns will again have appeared when you choose the code from the drop-down menu.

After filling the sections with the necessary information, now you may check the overall situation in the dashboard. So, you do not need to import any data here; only refresh the table by using the “refresh the table” button, charts and pivot table below will be renewed instantly.

Importantly, keep in mind that if there will be any changes in your data, you need to hit the “refresh the table” button again to update your chart. On the pivot table, you can check the inventory situation and the other variables like cost revenue, or profit for each product. Besides, there is a financial indication of categories and products at the top of the sheet.

Excel gives you a clear insight into how you can handle your inventory data and allows you to plan your stocks meticulously. It is a practical tool to use for the inventory management process, and this process is definitely a crucial path to optimize your sales and purchases. In the end, you would be built a well-done business strategy.

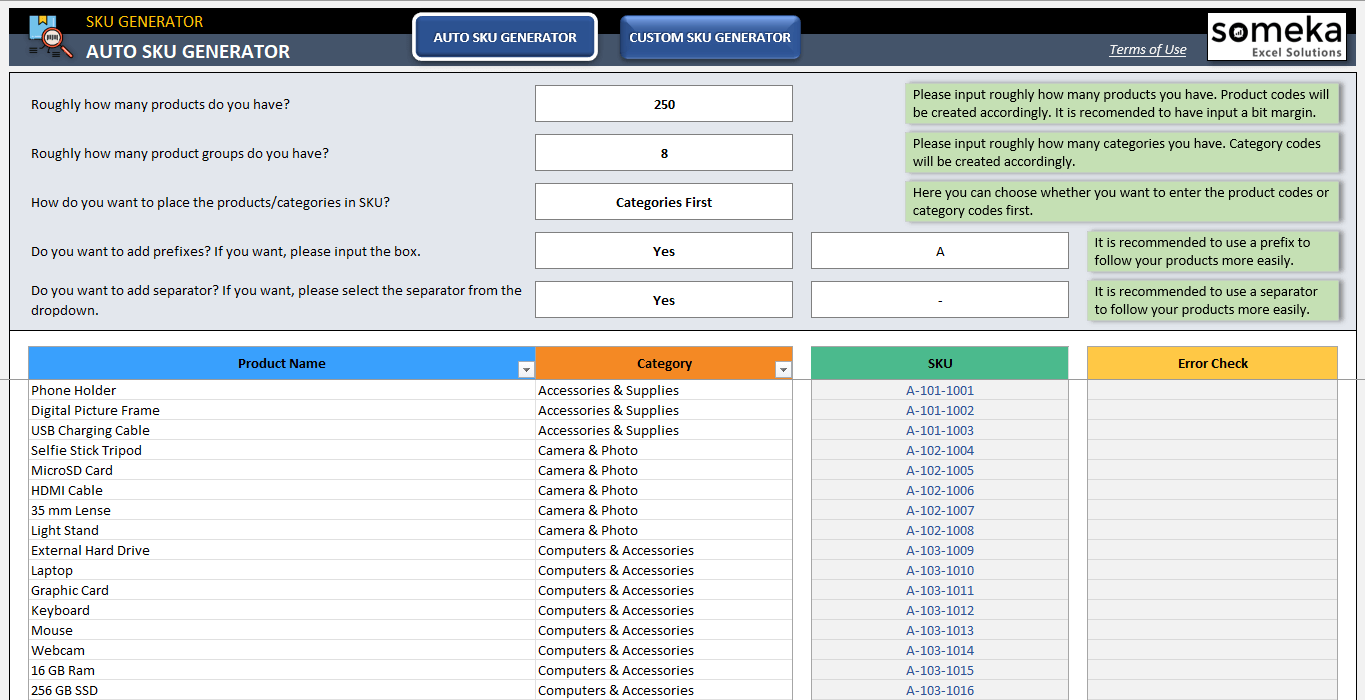

Besides, if you need some help creating SKUs, you can also download Someka SKU Generator Excel Template. Also, if you’re looking for a shareable file, you can check our SKU Generator Google Sheets Template. We can use both tools to create unique SKU numbers for products.

– This isa screenshot from Someka’s SKU Number Generator –

Final Words:

Finally, the Objectives of Inventory management are indispensable regardless of how large your business is. Also, it minimizes losses, and storage costs and prevents the company from stock-outs. These systems allow you to manage multiple locations effectively and provide accurate record-keeping.

In other words, an inventory solution saves you time and money by tracking everything systematically and fast; besides, this approach improves customer satisfaction by eliminating errors along the way and delivering them the best possible experience.

Also, having better customer relationships means better businesses. Thus, there is no doubt that inventory management systems highly and positively affect overall performance. Then, you can find the very right tool for your company and start enhancing your inventories.